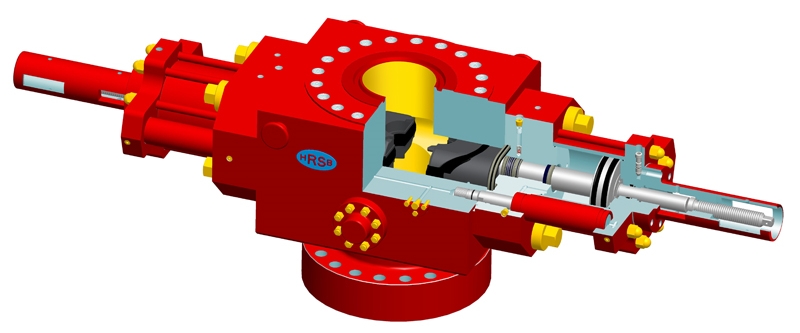

Ram BOP

A ram BOP is a blowout preventer that uses a pair of steel plungers that oppose each other (rams).

The Blowout Preventer (BOP) consists of two halves of a borehole cover that are separated from the middle. A large-diameter hydraulic cylinder, usually retracted, forces the two halves of the cover together in the middle to seal the borehole.

These covers are made of steel for strength and are fitted with elastomeric components on the sealing surface.

The two halves of the cap, formally known as the ram block, are available in a variety of configurations. In some designs, they are flat at the mating surface to seal open boreholes. Other designs have a circular cut-out in the middle, corresponding to the diameter of the pipe in the bore, to seal the well while the pipe is in the bore.

These pipe plungers effectively seal a limited range of pipe diameters. The rams can extend towards the wellbore's center to restrict the flow of fluids or retract open to permit the flow. Variable bore rams are designed to seal a wider range of pipe diameters, albeit at the expense of other design criteria, notably element life and suspension weight.

There are other rams fitted with tool steel cutting surfaces to enable the ram blowout preventer to shear the drill pipe completely, suspend the drill column from the ram itself, and seal the borehole. Clearly, such an action limits future options and is only used as a last resort to restore pressure control in the borehole.

Various ram blocks can be replaced in the ram blowout preventer, allowing the good team to optimize the blowout preventer configuration for a particular section of the well or for ongoing operation.

Ram BOP can be equipped with different types of rams, such as pipe rams, blind rams, shear rams, or variable-diameter rams, to meet different applications.

A pipe ram is a BOP ram that closes the annular space between the wellbore or blowout preventer and the pipe. It seals around the tubular outside diameter in the wellbore to restrict the flow of fluids through the annular space. A pipe ram does not obstruct the flow of fluids within the drill pipe. It shouldn’t be closed when there’s no pipe in the hole.

A closing and sealing component in a ram blowout preventer first shears certain tubular in the wellbore and then seal off the bore or acts as a blind ram if there is no tubular in the wellbore. This blowout preventer closing element uses hardened and fitted steel blades to cut the drilling pipes every moment the BOP gets closed. It then closes fully to seal the wellbore. Oilfield operators can use the shear rams to regain pressure control in the wellbore when other alternatives have failed. It always serves as the last resort.

The primary function of the blind ram BOPs is to cut off the openings for tubing or drill strings when there’s no production going on in the well. The Dual Shearing Blind Ram (DS) is a special type of ram BOP. It can cut through multiple tubing strings or tubular with larger diameters regardless of their orientation to the ram’s centerline. The DS by BOP Products can also serve as blind rams during normal drilling operations.

These rams are also known as the sealing shear rams. When the blowout preventer closes, the blind shear rams can cut the tubing or drill pipe. These ram Bops can also serve as the last resort when other BOP types have failed to regain pressure control.

HRSB manufactures ram blowout preventers in China. HRSB offers you high-quality and competitive prices for double-ram blowout preventers.

Contact us today for a quote on a double ram blowout preventer.

Related News of Rongsheng:

Rongsheng Technological Innovation

Rongsheng Launches Volunteer Service Activity